产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

蒸煮软化螺旋管 Cooking softening spiral pipe

一、简介

蒸煮软化螺旋管是一种典型成熟的蒸煮设备,尤其适用于重量轻、松散、流动性差、容易搭桥、滤水性差而又容易成浆的麦草、稻草、芦苇、杨木、竹子等原料。

一、Introduction

The cooking softening spiral pipe is a typical mature cooking equipment, especially suitable for wheat straw, straw, reed, poplar, bamboo and other raw materials which are light in weight, loose, poor in fluidity, easy to bridge, poor in drainage and easy to be pulped。

二、蒸煮软化螺旋管的优点:

根据原料,制浆方法及产品质量的不同,与间歇式蒸煮设备相比,它的优点有:

A、实现连续蒸煮生产、自动化程度高,变频传动,蒸煮时间可调;

B、蒸汽、电力消耗均衡,没有高峰负荷,不需要高压力。

C、占地面积相对较小,产量高,吨浆蒸汽消耗较低。

D、用水量少,蒸汽升温速度快,制浆浓度高、原料熟化快。

E、封闭式连续生产,减少工人劳动力,降低生产成本。

F、转速低轴承使用寿命长,易于操作管理。

蒸煮反应螺旋输送管是秸秆制浆行业的发展趋势,优点比较明显。

二、Advantages of cooking softening spiral pipe:

According to the different raw materials, pulping methods and product quality, compared with batch cooking equipment, its advantages are:

A、Realize continuous cooking production, high degree of automation, variable frequency drive and adjustable cooking time.;

B、Steam and electricity consumption are balanced, there is no peak load and no need for high pressure.。

C、Relatively small floor space, high output and low steam consumption per ton of pulping.。

D、Less water consumption, fast steam heating speed, high pulping concentration and fast raw material curing.。

E、Closed continuous production reduces workers' labor force and production cost.。

F、The bearing with low rotating speed has long service life and is easy to operate and manage.。

The spiral conveying pipe for cooking reaction is the development trend of straw pulping industry, and its advantages are obvious.

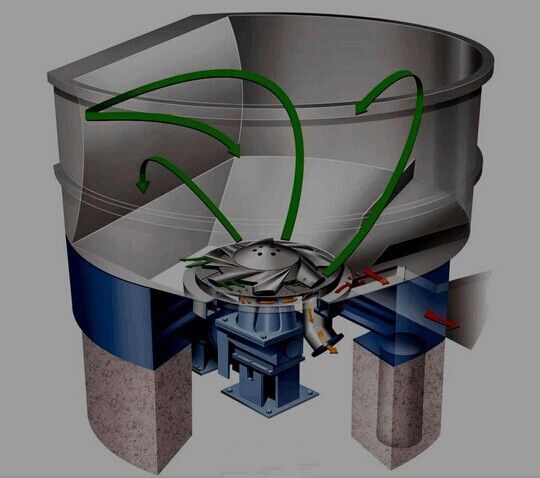

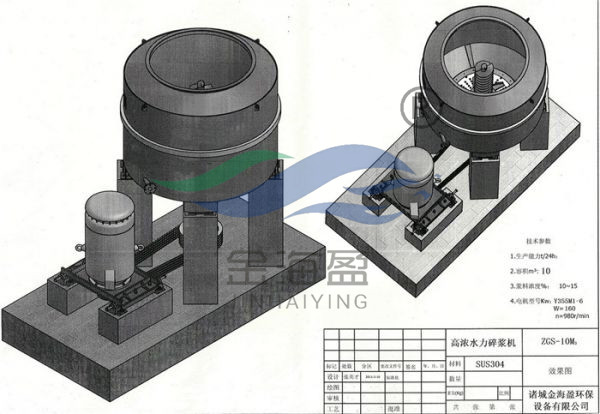

横管蒸煮反应器彩页图片: