产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

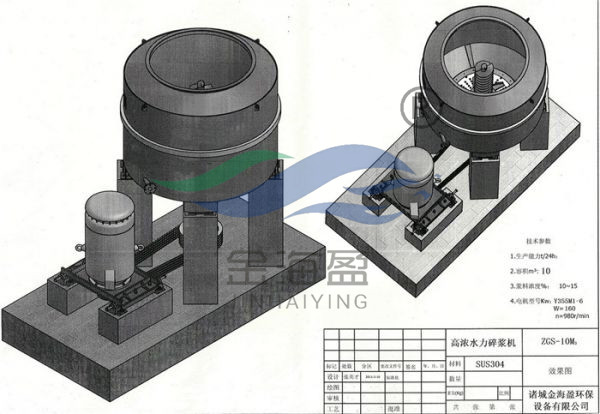

液压高浓磨浆机 Hydraulic pressure High consistency refiner

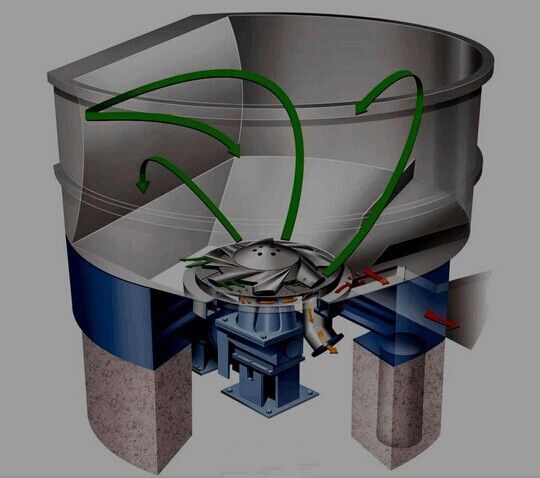

二、理想的疏解打浆原理:

高浓度磨浆过程,植物纤维在两磨盘之间撑起两面磨盘的间隙,使磨盘没有真正碰到一起,主轴上的移动磨盘有很高的推力,在1500转的高转速下压溃疏解纤维,所以剪切力降低,保证纤维不被切断。植物秸秆纤维化的过程来自于两副磨盘的强力压溃和纤维之间的相对搓揉,使纤维分丝帚化,完成疏解磨浆过程。高浓度磨浆机对物料适应范围广,无论是木材,竹子、稻草、麦草、蔗渣、废纸等原料,都能够以其较高的线速度和适当的磨片间隙疏解分离成优质的纤维原料。

一、Ideal principle of defibering and beating:

In the process of high-concentration pulping, the plant fiber propped up the gap between the two millstones, so that the millstones did not really touch each other. The moving millstones on the spindle had high thrust, which crushed and loosened the fiber at a high speed of 1500 revolutions, so the shear force was reduced, and the fiber was not cut off.。The process of plant straw fibrosis comes from the strong crushing of two grinding discs and the relative rubbing between fibers, which makes the fibers split and broom, and completes the process of defibering and refining。High-concentration refiners have a wide range of applications to materials. No matter wood, bamboo, rice straw, wheat straw, bagasse, waste paper and other raw materials, they can be separated into high-quality fiber raw materials with high linear speed and proper grinding gap。

三、与低浓磨浆机的比较有明显的优点:

3.1、节能:吨浆电耗节省20﹪~40﹪.

3.2、节水:吨浆节省用水60﹪以上.

3.3、高效:能使纤维物理强度指标提高10﹪~20﹪.

3.4、柔性打浆:能使原料在含水率极低的状态下进行挤压、摩擦、揉搓等做功状态疏解成优质的纤维,从而使植物秸秆充分分丝、帚化、纤维化。

3.5、高浓疏解纤维优点:秸秆原料含水率低,在高压搓揉作用下迅速升温,改变纤维结构,分离纤维束,将木质素在助剂软化分解过程中利用磨盘间磨齿的压溃剥离作用,将木质素剥离至纤维表面,与纤维分离,提高纤维质量,降低木质素对纤维的影响。

3.6、润滑和冷却:具有特别的轴承稀油润滑和轴承稀油、水双冷却系统,有效保证轴承的润滑和冷却,保证主机正常运行。

3.7、本机采用独特的机械传动和液压设计,优化的磨片组合,简捷的磨片间隙调节方式,操作方便灵活、运行稳定可靠、维修方便快捷、外形美观大方。充分体现了人机合一的完美组合。

三、Compared with low consistency refiner, it has obvious advantages:

3.1、Energy saving: the power consumption per ton of pulp is saved by 20%~40%.

3.2、Saving water: saving water by over 60% per ton of pulp;

3.3、High efficiency: it can improve the physical strength index of fiber by 10%~20%.

3.4、Flexible beating: The raw materials can be extruded, rubbed, kneaded, etc. under the extremely low water content to be decomposed into high-quality fibers, so that the straw can be fully divided, brushed and fiberized.

3.5、Advantages of high-consistency coarse grinding and shredding: the moisture content of straw raw materials is low, and the temperature rises rapidly under the high-pressure thrust and kneading of two millstones, realizing a short cooking process. At high temperature, the fiber becomes soft and tough and will not be cut. Extruding lignin from fiber can improve fiber quality and reduce the influence of lignin on fiber.

3.6、Lubrication and cooling: It has special bearing lubrication and cooling system, oil cooling and water cooling, and dual cooling system, which effectively ensures the service life of bearings and the normal operation of the main engine。

3.7、This machine adopts unique mechanical transmission and hydraulic design, unique combination of grinding plates, simple adjustment mode of grinding plate gap, convenient and flexible operation, stable and reliable operation, convenient maintenance and beautiful appearance. Fully embodies the perfect combination of man-machine integration.