产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

一、多辊筛分除尘机特征性能介绍:

多辊筛分除尘机是配套秸秆清洁制浆工艺流程中的备料设备,功能是筛分、除尘净化作用。适用于麦草、稻草、芦苇、蔗渣等原料。收购的草类秸秆原料内总会夹杂着部分泥、砂、土尘等杂质,这部分杂质不筛除,会对后续设备造成严重磨损及破坏,还会影响制成的纤维灰分大、质量不合格的因素。

一、Multi-roller screening dust collector:

Multi-roller screening dust collector It is a necessary equipment for raw material screening and dust removal in straw clean pulping process。Suitable for the screening and dust removal process of straw and wheat straw。The purchased wheat straw and straw will be mixed with a lot of mud, sand, dust and other sundries,If these impurities are not screened out, the ash content of the fiber will be unqualified, and the equipment for subsequent processing will be damaged。It will also affect the factors of high ash content and unqualified quality of the fiber.

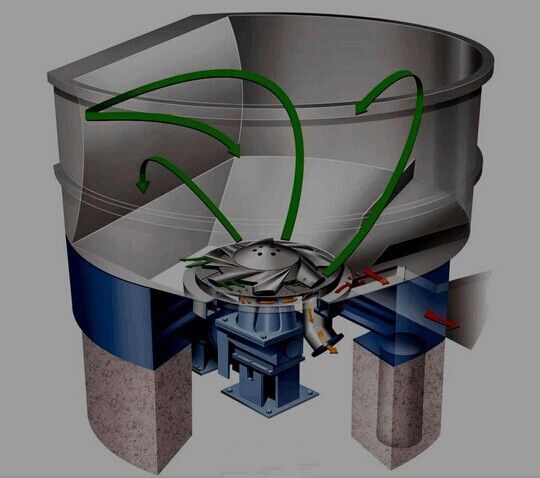

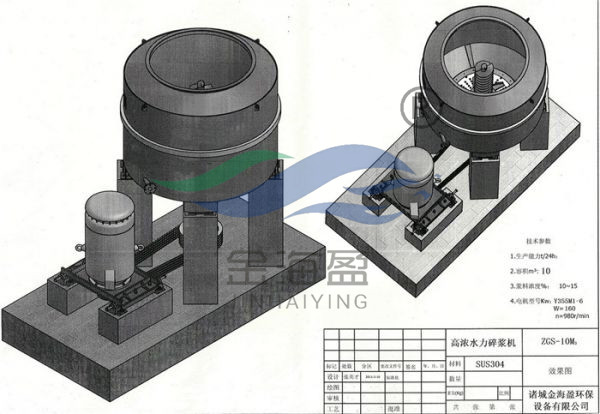

二、进入原料要求及工作原理:

要求投入原料长度在3-8厘米之间,由切草机切草后直接送至多辊筛分除尘机内,该设备一般由4-6组翻抛辊组成,辊子的周围安装着翻抛草料的叉板,类似于羊角,所以我们也称之为羊角辊。每组翻料辊的底部都装有过滤泥砂的筛板,筛板装拆采用快插式结构设计,便于快速抽出和更换。麦秸物料由进料口进入筛分除尘器。在羊角辊高速旋转并不断向前运动的同时,给料机翻转,给料机在此过程中实现了筛分、除渣过程。将混入麦秸中间的泥、细砂、粉尘等杂质进行摔打、抛掷、分离,较重的泥、砂通过底部的筛孔落下,与麦秸原料分离。顶部的空气除尘装置将极细的粉尘吸出并分离。细粉尘进入除尘设备的脉冲除尘器收集净化后的空气后在高空放。干净的稻、麦草秸秆从水平出料口抛入皮带机,进入下一道工序。

二、Input raw material requirements and working principle:

It is required that the length of the input raw materials is between 3-8 cm, and the grass is cut by the grass cutter and sent directly to the multi-roller screening dust remover. This equipment is generally composed of 4-6 groups of turning rollers, and fork plates for turning and throwing grass are installed around the rollers, which are similar to the horns, so we also call them claw rollers。The bottom of each turning roller is provided with a sieve plate for filtering mud and sand。

The sieve plate is assembled and disassembled with quick plug-in structure design, which is convenient for quick extraction and replacement。Wheat straw material enters the screening dust collector from the feed inlet. While the goat horn roller rotates at high speed and keeps moving forward, the feed is turned over, and the feed realizes the screening and slag removal process in this process。Impurities such as mud, fine sand and dust mixed in the middle of wheat straw are beaten, tossed and separated, and heavier mud and sand fall through the sieve holes at the bottom and are separated from wheat straw raw materials。Very fine dust is sucked out and separated by the air-induced dust removal device at the top。Fine dust enters the pulse dust collector of dust separation equipment to collect purified air and then is released at high altitude。Clean wheat straw is thrown into the belt conveyor from the horizontal discharge port,Enter the next process。