产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

秸秆粗磨分丝机 Straw coarse grinding and defibering machine

一、设备简介:

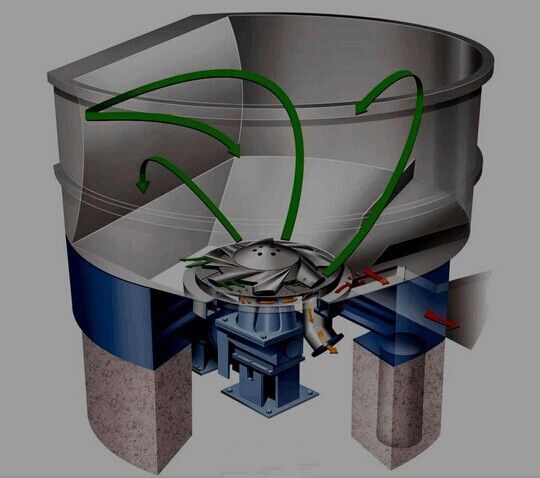

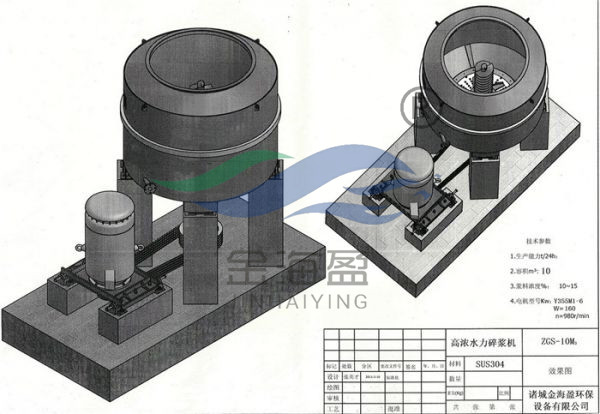

JGS系列自动控制秸秆粗磨分丝机,是我公司自主研发的一款新型高浓度进料、节能型粗磨分丝设备,该设备为液压自动化控制,具有操作灵活、移动精度高、反应灵敏等优点。磨机静磨盘采用特殊材料配置、按磨盘模具尺寸压制成形、经过高温烧制定型制造,具有硬度高、耐磨损的特点。表面类似于磨刀石,无论怎样磨损表面始终象石头表面一样略带粗糙,所以在对秸秆的研磨过程中尽量避免纤维被切断,保持纤维长度。分丝效果特别好。

一、Brief introduction of equipment:

JGS series automatic control straw coarse grinding and shredding machine is a new type of high-concentration feeding and energy-saving coarse grinding and shredding equipment independently developed by our company. The equipment is hydraulic automatic control and has the advantages of flexible operation, high moving accuracy and sensitive response。The static grinding disc of the mill is made of special materials, pressed and shaped according to the size of the grinding disc die, and fired and shaped at high temperature, which has the characteristics of high hardness and wear resistance。The surface is similar to a grindstone, no matter how worn, the surface is always slightly rough like the stone surface, so try to avoid the fiber being cut off and keep the fiber length in the grinding process of straw。The fiber splitting effect is particularly good。

二、秸秆粗磨分丝机有以下几个特点:

1.磨片齿间槽齿宽,便于高浓度进料,进料量大,大块或者较长的原料都可以比较容易的进入磨区。

2.磨盘采用特殊原料模压成型,经高温烘烤而成。磨片表面类似于磨刀石,略有粗糙感,在秸秆研磨过程中切不断纤维,特别适用于阔叶木和速生植物秸秆,这些原料特点就是纤维短、强度低,在研磨过程中容易被切断。特别是对于烟筋、麦草、稻草、龙须草、甘蔗渣等速生植物,本身植物纤维就短的原料,有很好的保护作用。

3.动盘采用合金铸造磨盘,因为合金磨盘可以校正动平衡,拆卸方便。配合树脂砂磨盘使用,通过量大,纤维压溃疏解效果好,磨浆时纤维升温速度快,纤维软化好,疏解帚化效果好。树脂砂磨盘与合金磨盘可以互换的,可以根据原料要求更换磨片,一对合金配套或者一片合金一片树脂磨盘使用。

4、对原料适应范围广,例如:稻草、麦草、芦苇、棉杆、甘蔗渣、沙柳等。

二、The main features are as follows:

1.The tooth surface of the grinding plate and the feed groove are both wide, which is beneficial to high-concentration feeding and large feed volume,Coarse or long raw materials can easily enter the grinding zone.。

2.The grinding disc is molded with special raw materials and baked at high temperature. The surface of the millstone is similar to a millstone, which has a little rough feeling. The fiber will not be cut off during the grinding of straw, and it is especially suitable for hardwood and fast-growing plant straw. These raw materials are short fibers and low strength, which are easy to be cut off during grinding。Especially for fast-growing plants such as tobacco, wheat straw, rice straw, Chinese alpine rush, bagasse, etc., the raw materials with short plant fibers have a good protective effect.。

3、The dynamic disk adopts alloy casting grinding disc, because the alloy grinding disc is suitable for correcting dynamic balance and easy to disassemble. When used with resin sand grinding disc, it has large throughput, good fiber crushing and defibering effect, fast fiber heating speed during pulping, good fiber softening and good defibering effect。The positioning dimensions of the resin grinding disc and the alloy grinding disc are the same, and the grinding disc can be replaced according to the requirements of raw materials。Two pairs of alloy grinding plates or one pair of alloy grinding plates and one pair of resin grinding plates are used.

4、Wide adaptability to raw materials, such as rice straw, wheat straw, reed, cotton stalk, bagasse, Salix psammophila, etc.