产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

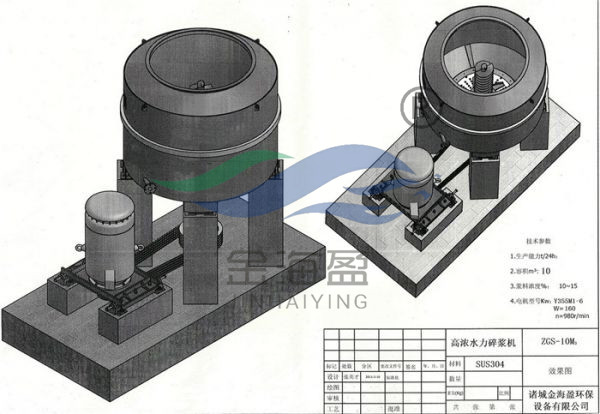

高浓碎纸制浆机High-concentration shredded paper pulping machine:

一、高浓碎纸制浆机简介:

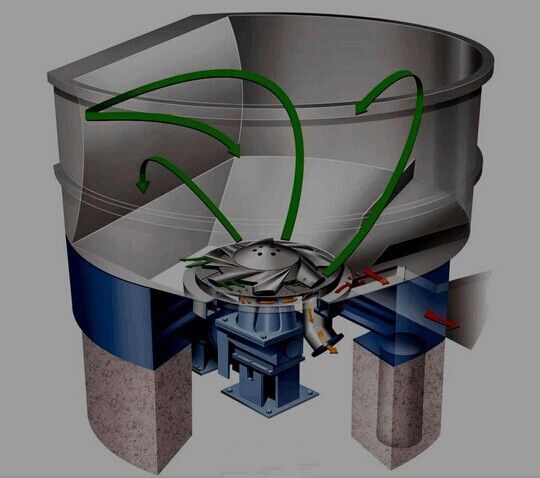

高浓度碎纸制浆机是废纸脱墨制浆的高浓揉搓碎解设备。适用于书本纸、静电复印纸、报表杂志纸、报纸等废纸(纸浆浓度为10-16%)。废纸通过机械力、热水浸泡和表面活性剂的渗透软化、脱墨剂和剥离剂的共同作用,使其软化、分散、油墨分离,将印刷的油墨从纸张表面和纤维上剥离。

一、Brief introduction of high concentration shredded paper pulping machine:

High-concentration shredded paper pulping machine is a high consistency kneading and breaking equipment for deinking pulp of waste paper. Suitable for waste paper such as book paper, electrostatic copy paper, report magazine paper, newspaper, etc. (pulp crushing concentration is 10-16%). Waste paper is softened by mechanical force, soaking in hot water and osmotic softening of surfactant, and by the combined action of deinking agent and stripping agent,Dispersion, ink separation, stripping the printed ink from the paper surface and fiber.。

二、高浓度碎纸制浆机的特点:

1、高浓度碎浆机具有碎浆浓度高的特点,碎浆浓度在12%-18%之间,用于废纸脱墨浆的处理可大大降低浆料加热能耗和化学药品的消耗量,纸页和纤维之间摩擦力量大、通过螺旋绞龙的剥离疏解效果好,促使油墨粒子从纤维上更快地剥离和分散;而且对单根纤维几乎没有切断作用;对杂质的破坏作用小等优点。

2、放料稀释装置能使高浓浆料无须在碎浆机筒体内稀释而直接放料,大大缩短高浓浆料的放料时间,降低设备动力,节约电耗,能均匀准确的控制浆料的浓度。

二、Characteristics of high concentration shredded paper pulping machine:

1、High-concentration pulper has the characteristics of high pulp breaking concentration, and the pulp breaking concentration is between 12% and 18%. It can greatly reduce the energy consumption of pulp heating and the consumption of chemicals when used for deinked pulp of waste paper. The friction between paper and fiber is large, and the stripping and loosening effect by screw auger is good, which promotes the ink particles to be stripped and dispersed from the fiber more quickly. But also has almost no cutting effect on a single fiber; Small damage to impurities and the like.

2、The discharging dilution device can directly discharge the high-consistency slurry without dilution in the barrel of the pulper, which greatly shortens the discharging time of the high-consistency slurry, reduces the power of the equipment, saves power consumption, and can control the concentration of the slurry evenly and accurately