产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

木片摇摆筛Chip swing screening machine:

一、用途与特点:

本设备用于竹片、木片的筛选,去除大块和碎末,获得合格木片。本设备具有单位面积生产能力大,动力消耗低,占地面积小,操作维修简单,运行可靠等优点。

一、Uses and characteristics:

This equipment is used for screening bamboo chips and wood chips, removing large pieces and scraps to obtain qualified wood chips. This equipment has the advantages of large production capacity per unit area, low power consumption, small floor space, simple operation and maintenance, reliable operation and so on.

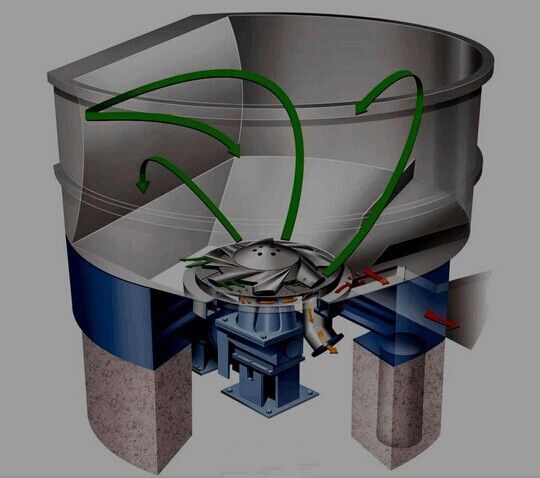

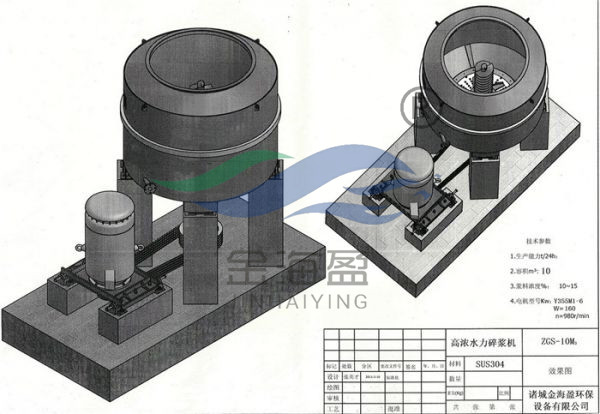

二、主要结构及工作原理:

本设备由基础支架,筛体,激振装置,传动装置,万向节拉杆及进出料斗等组成,如附图所示。筛体通过四个万向节拉杆悬挂在大支架上,配重装置安装在筛体的中心,筛体外侧的电机通过传动机构带动激振装置旋转,安装在轴上的偏心块旋转产生的离心力带动筛体作平面360度摇摆晃动,筛板的安装是结构是向出料口倾斜的,木片在连续强烈的摇振下迅速滑向出料口,从而完成木片和皮渣的筛分过程。筛体由焊接的筛框和筛板组成,上下两层筛板用螺钉固定在筛框上,筛板沿出料方向倾斜7°,以提高通过能力和分离效率。筛体在摇摆过程中,木片沿筛板表面滑动并下移,合格木片通过上层筛板筛孔落在下层筛板上,最后从合格片出料口排出,碎未通过上下两层筛板筛孔落在筛体底板上,最后从碎未出口排出。大块不能通过上层筛孔的长条,沿上层筛板表面下移到大块出口排走。

二、Main structure and working principle:

This equipment consists of a foundation bracket, a screen body, an exciting device, a transmission device, a universal joint pull rod, a feed hopper and the like, as shown in the attached figure。The screen body is hung on the big bracket through four universal joint pull rods, and the vibration exciting device is installed in the center of the screen body. The motor outside the screen body drives the vibration exciting device to rotate through the transmission mechanism, and the centrifugal force generated by the rotation of the eccentric block installed on the shaft drives the screen body to swing and shake in a plane of 360 degrees. The screen plate is installed in a structure inclined to the discharge port, and the wood chips quickly slide to the discharge port under continuous and strong shaking, thus completing the screening process of wood chips and skin dregs.。The screen body consists of a welded screen frame and a sieve plate. The upper and lower sieve plates are fixed on the screen frame by screws, and the sieve plates are inclined by 7 degrees along the discharging direction to improve the passing capacity and separation efficiency。During the rocking process of the sieve body, the wood chips slide along the surface of the sieve plate and move down. The qualified wood chips fall on the lower sieve plate through the sieve holes of the upper sieve plate, and finally are discharged from the qualified sheet discharge port. The broken chips fall on the bottom plate of the sieve body through the sieve holes of the upper and lower sieve plates, and finally are discharged from the broken outlet. The large strips that can't pass through the upper sieve holes move down along the surface of the upper sieve plate to the outlet of the large pieces to be discharged.

三、木片摇摆筛的型号、筛选面积、孔径可根据相关的产量和木片大小要求定制。

三、The model, screening area and aperture of chip swing screen can be customized according to the relevant output and chip size requirements。