产品展示

- 电话总机:400 8825788

- 传真:0536-6512296

- 售后:13563697757

- 邮箱:250158177@qq.com

- 地址:山东省潍坊市诸城市龙都街道西外环路中段西侧

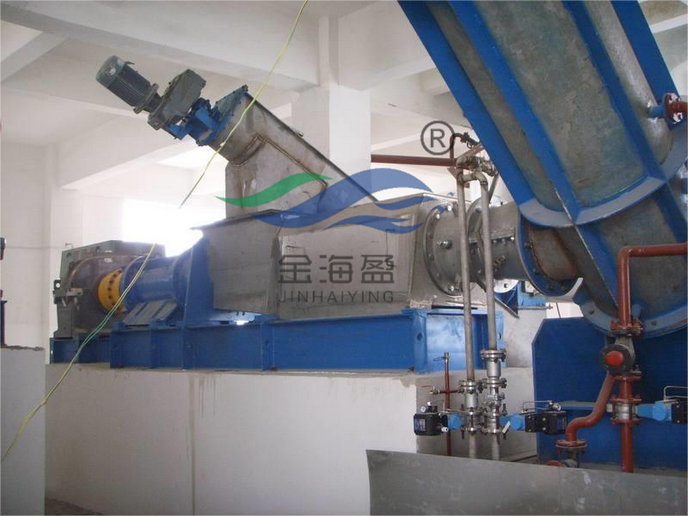

螺旋压榨破碎机

Screw press crusher

一、螺旋压榨破碎机技术特征:

螺旋压榨破碎机顾名思义就是,利用强制挤压技术将木片、竹片等原料利用螺旋压缩原理强制挤压,至原料结构破裂,将植物纤维之间的水份、糖份、植物胶等成分通过强制压榨挤出来一部分。挤出木材、竹子植物内的汁液后,将显著降低蒸煮制浆过程中溶解的木质素,缩短蒸煮软化时间,降低溶解液的处理成本...压榨脱水后的原料中空、结构疏松,有利于药液的吸收,缩短蒸煮时间。挤压后的纤维对药液吸收快,药液容易进入纤维内,使原料中的木质素快速降解。

一、Overview of screw press crusher:

As the name implies, the screw press crusher uses the forced extrusion technology to forcibly squeeze raw materials such as wood chips and bamboo chips by the principle of screw compression until the structure of raw materials is broken, and some components such as water, sugar and plant gum between plant fibers are squeezed out by forced extrusion,After squeezing out the juice from wood and bamboo plants,

the lignin dissolved in the process of cooking and pulping will be significantly reduced, shortening the cooking softening time and reducing the treatment cost of the dissolved solution.。The squeezed and dehydrated raw materials are hollow and loose in structure, which is beneficial to the absorption of liquid medicine and shortening cooking time。The squeezed fiber absorbs the liquid medicine quickly, and the liquid medicine can easily enter the fiber, so that the lignin in the raw material is degraded quickly。

二、用途二:

低温浸泡的竹片、木片经本设备压榨脱水后含水率低于50%,达到了压榨脱水的极限,方便了运输,降低了运输成本。挤压的另一个优点是保护纤维,因为竹子、桉树、杨树等植物生长速度快,纤维短。为了保护纤维的长度和强度,打浆和打浆前的备料和前处理是非常重要的。

The moisture content of bamboo chips and wood chips soaked at low temperature after being squeezed and dehydrated by this equipment is lower than 50%, which has reached the limit of squeezing and dehydration, which is convenient for transportation and reduces transportation cost。Another advantage of extrusion is to protect fibers, because bamboo, eucalyptus, poplar and other plants grow fast and have short fibers. In order to protect the fiber length and strength, it is very important to prepare materials and pretreatment before beating and refining

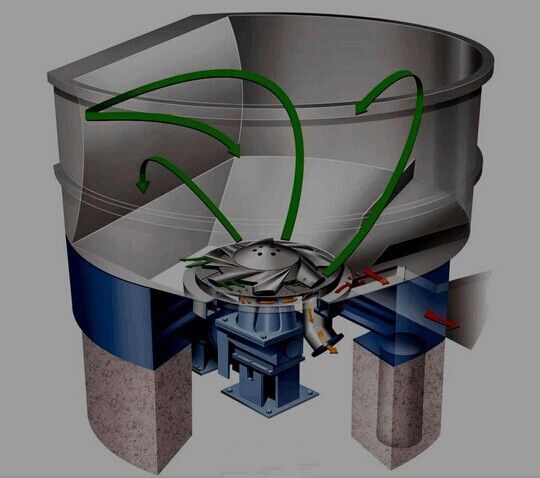

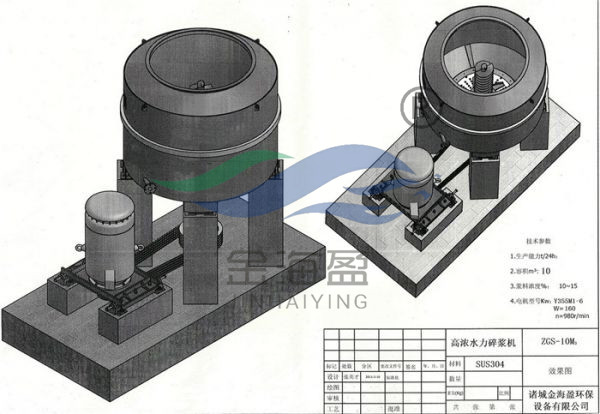

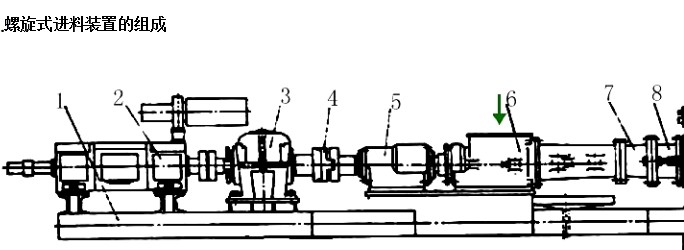

二、挤压疏解机装置组成:

1、基础板;2、直流电机;3、减速器;4、硬连接器;5、轴承体;6、进料口

7、挤压疏解区;8、出料端口 1. Foundation plate; 2. DC motor; 3. reducer; 4. Hard connector;

5. Bearing body; 6. Feed inlet 7. Extrusion crushing area; 8. Discharge throat

三、设备实物: